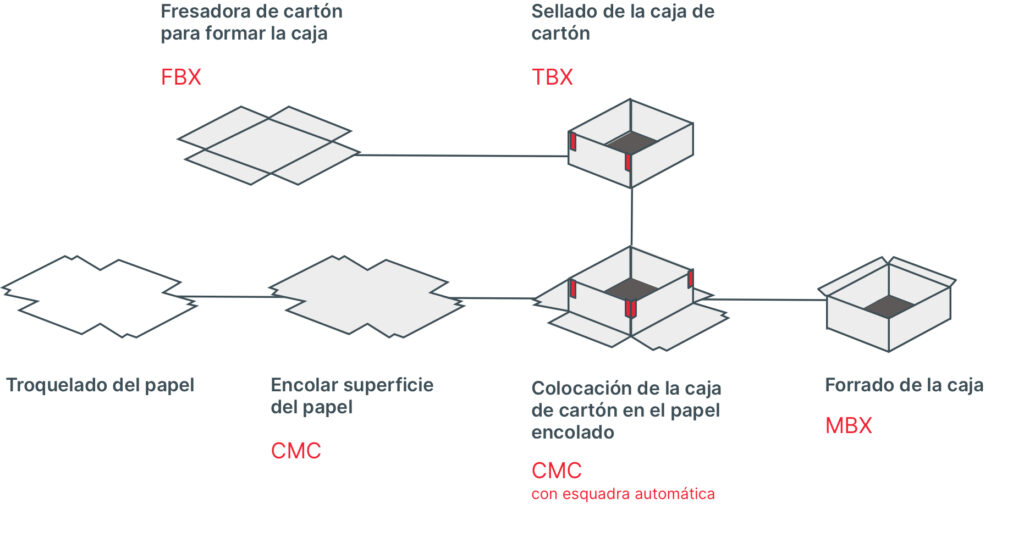

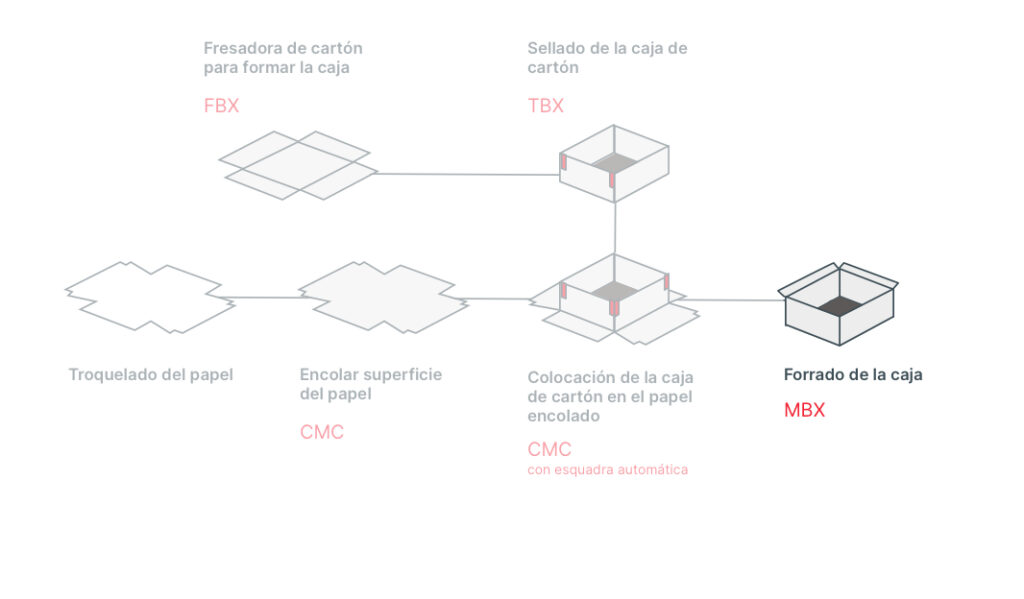

Packaging machinery

We offer the best customized solutions for small, medium and large lined box production at all stages of the production process.

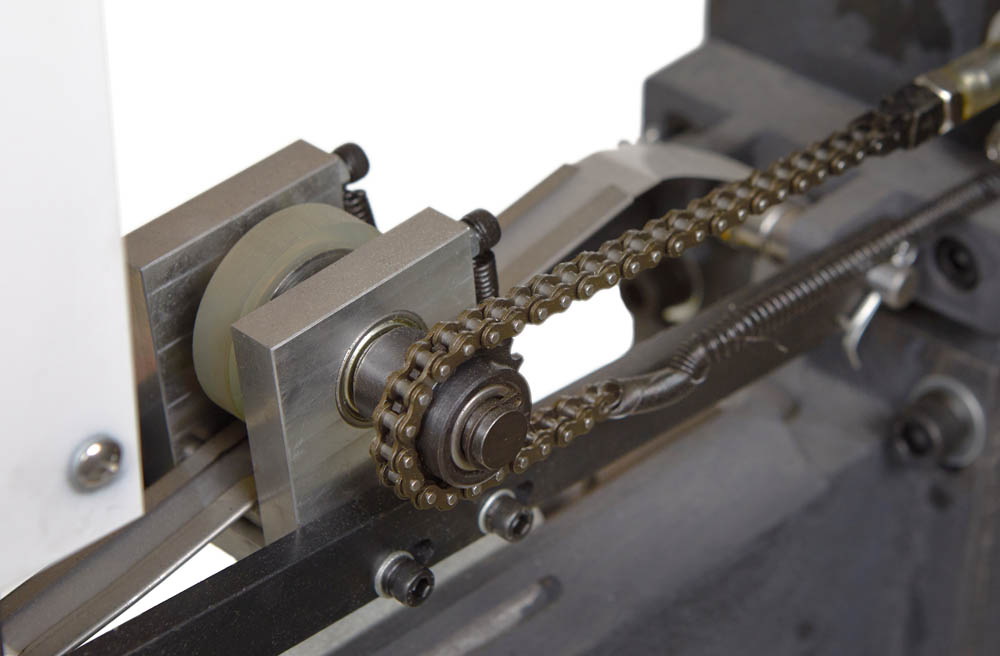

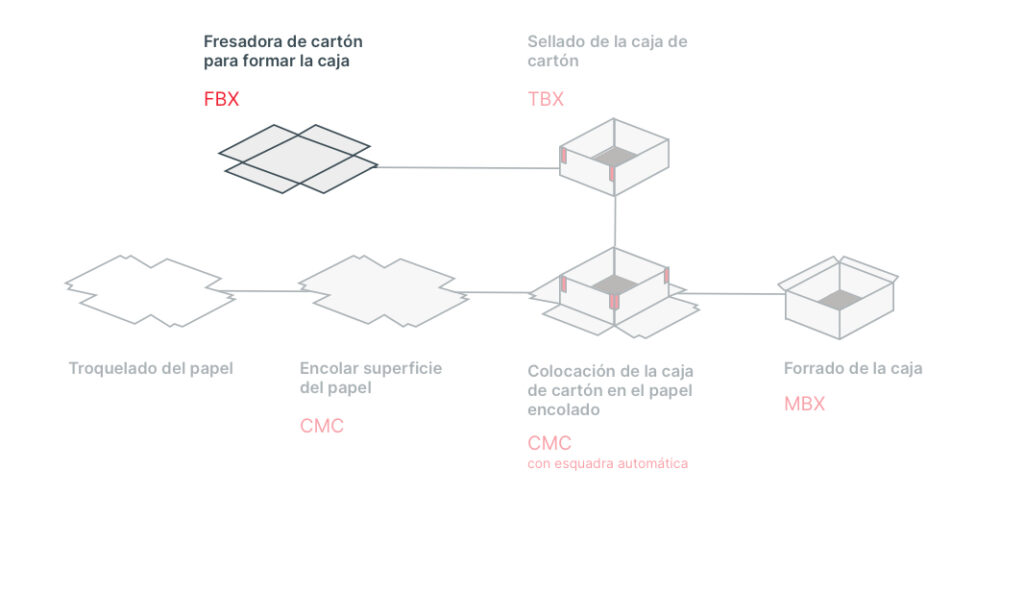

Grooving machines

The first step in the production of a lined box is to shape the cardboard. Our grooving machines cut at 90º angles for a perfect closure of the box, and at 120º for the closure of chest boxes.

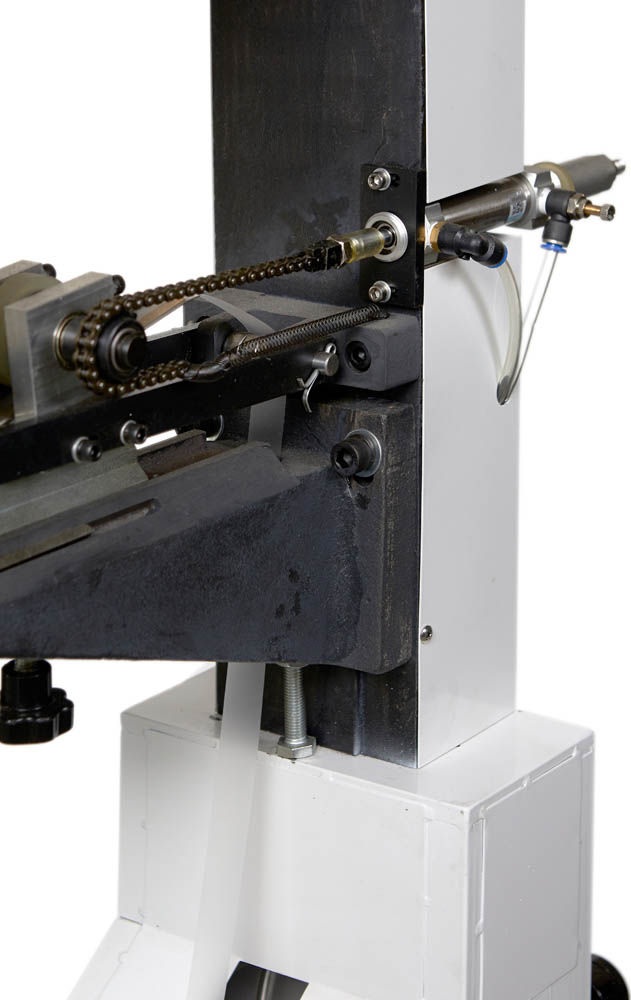

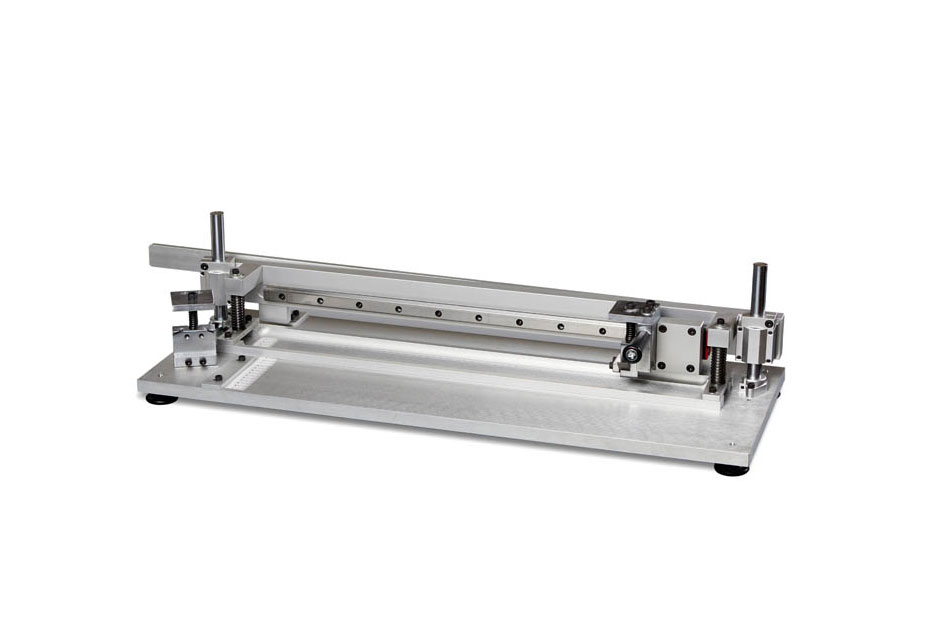

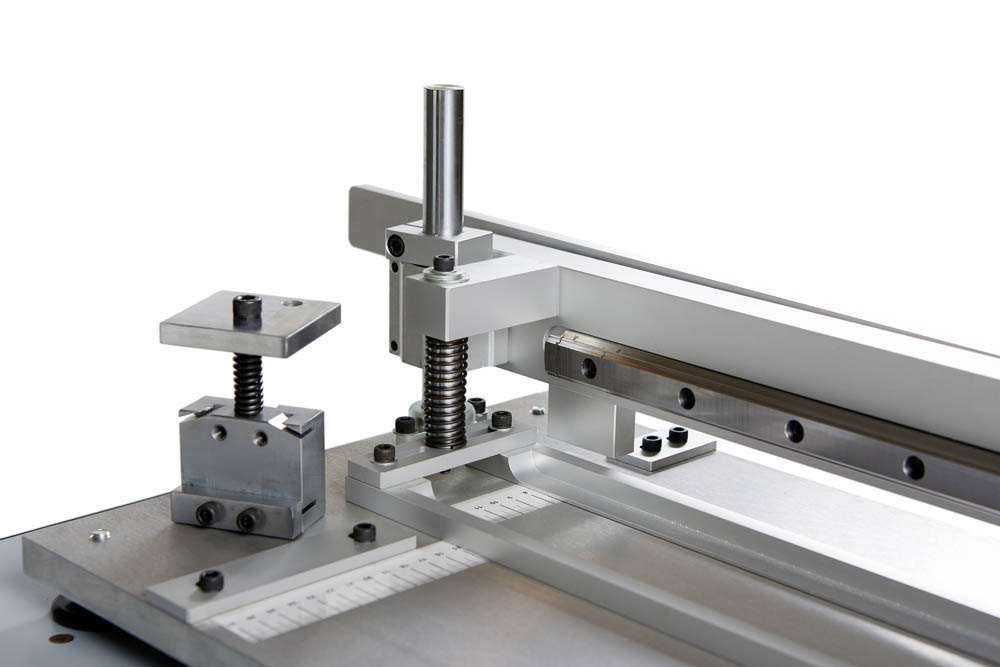

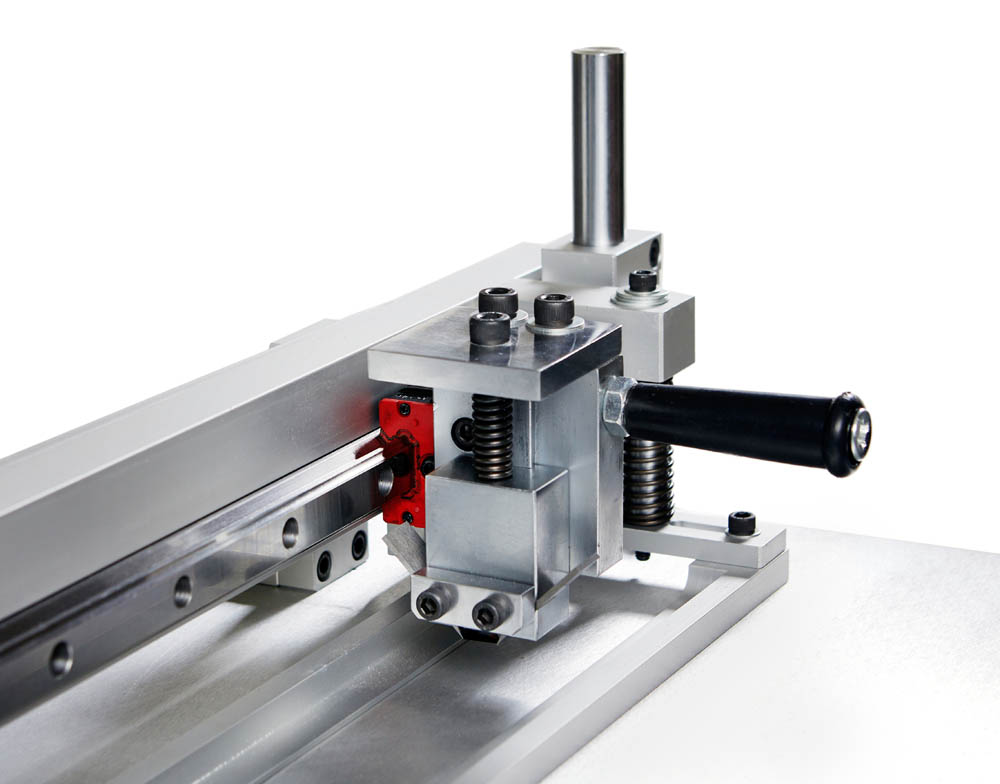

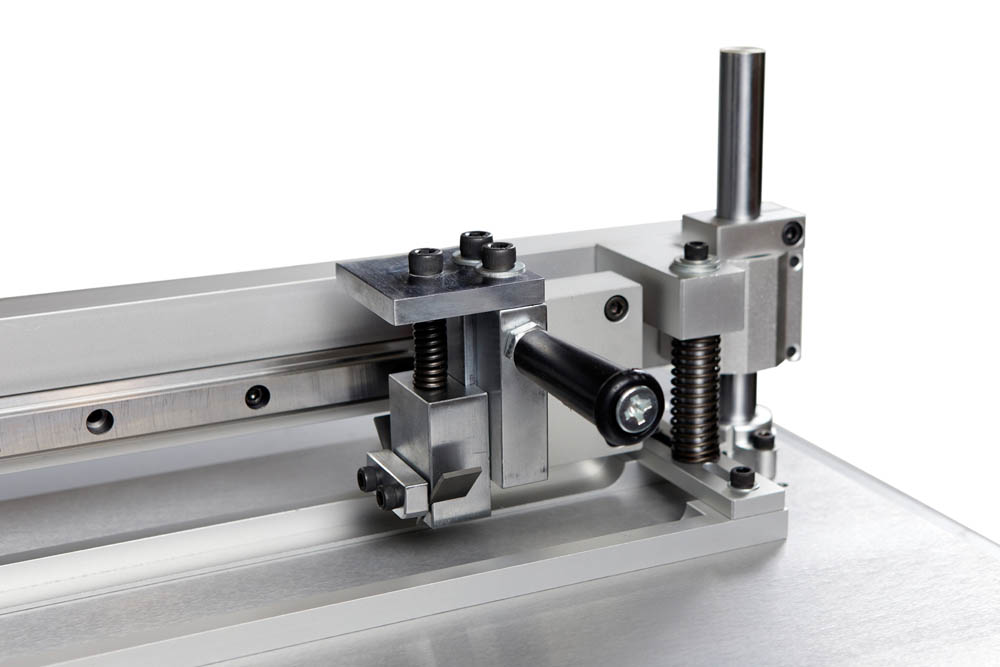

FBX-MANUAL

The FBX-M1 grooving machine is designed to groove cardboard sheets. These groovings serve to be able to mold the cardboard according to convenience, make different slots, packaging pieces, bases for boxes, etc…

- 90 and 120º groove

- Versatile and reliable, very easy handling

- Metric for precise fit

- Easy and intuitive blade change

FBX-CUT

High production board die cutting machine Best solution to work along with our FBX-L3 grooving machine

- Replaces previous die cutting

- No mold needed

- High production speed

- 3 servomotors for automatic adjustment

- Optional: Conveyor belt (600 x 1500 mm)

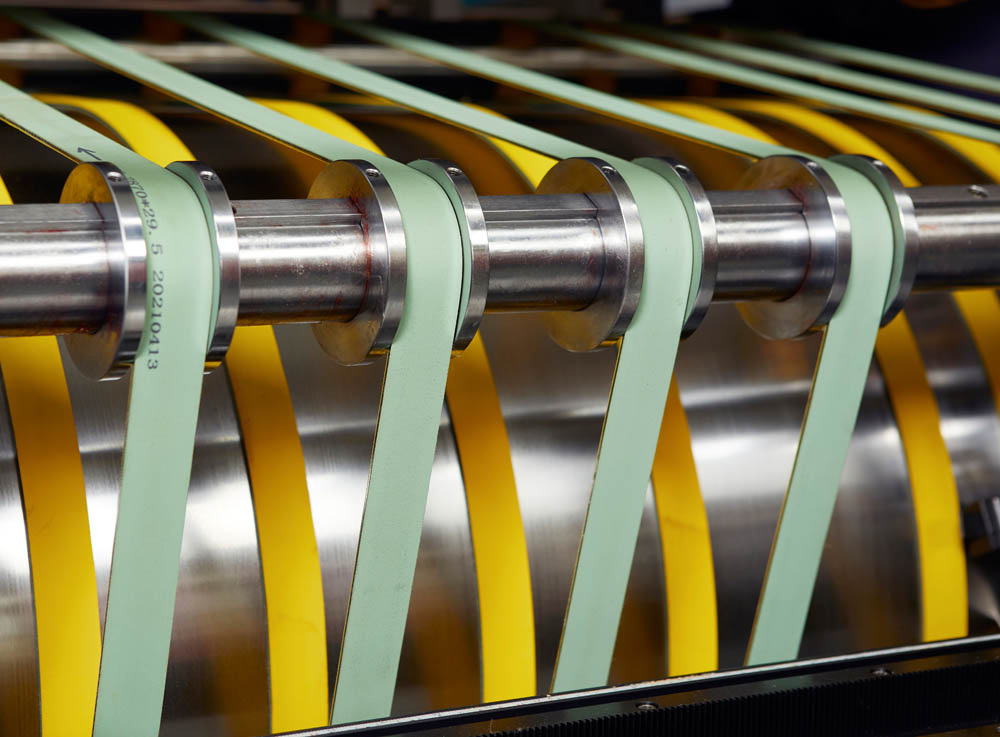

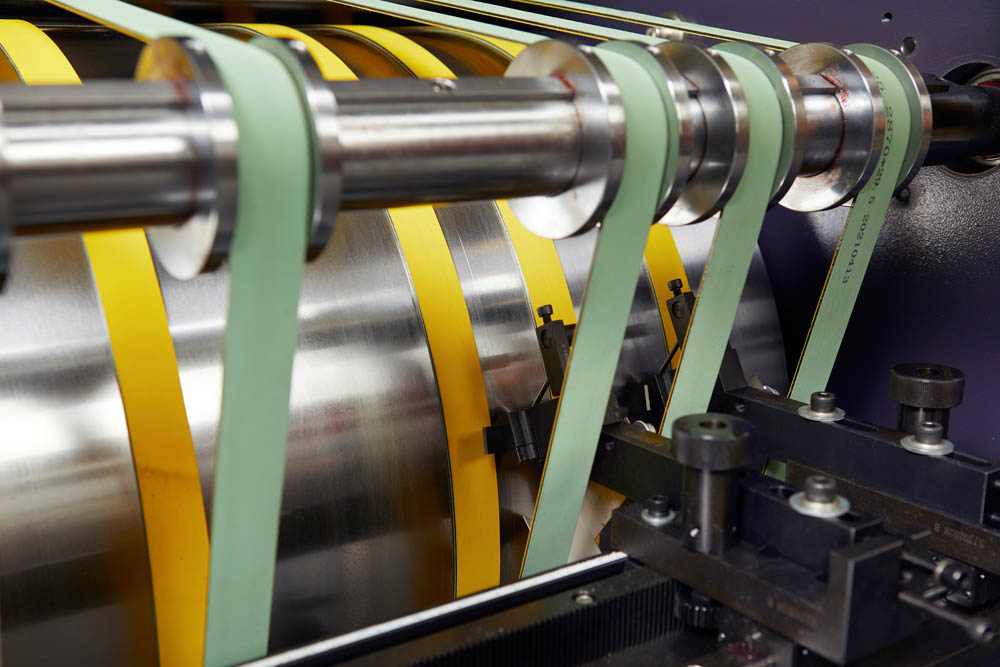

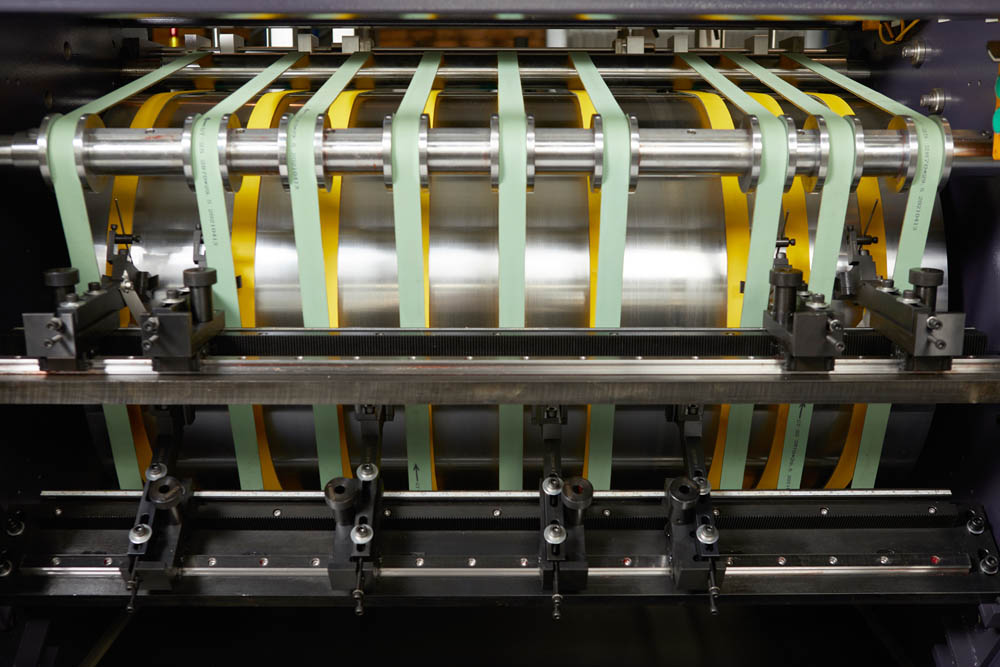

FBX-L1

Automatic drum grooving machine, with double charger for the production of both sides of the box in continuous production.

- 90 and 120º groove

- Up to 8 simultaneous grooving

- High production speed

- Maximum cardboard width 110 cm

- Speed: 35pcs/min.

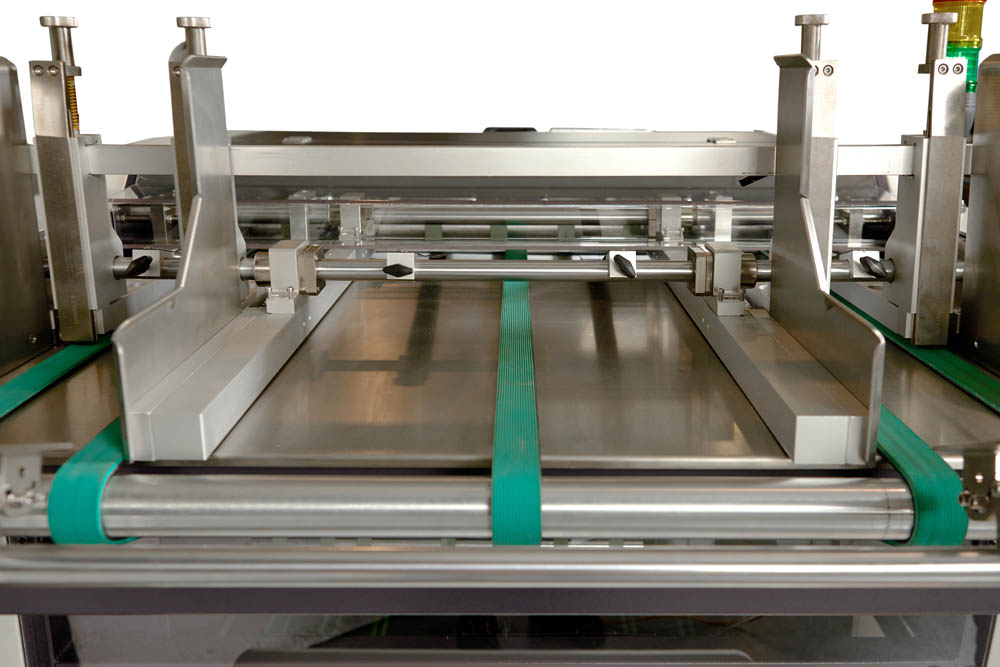

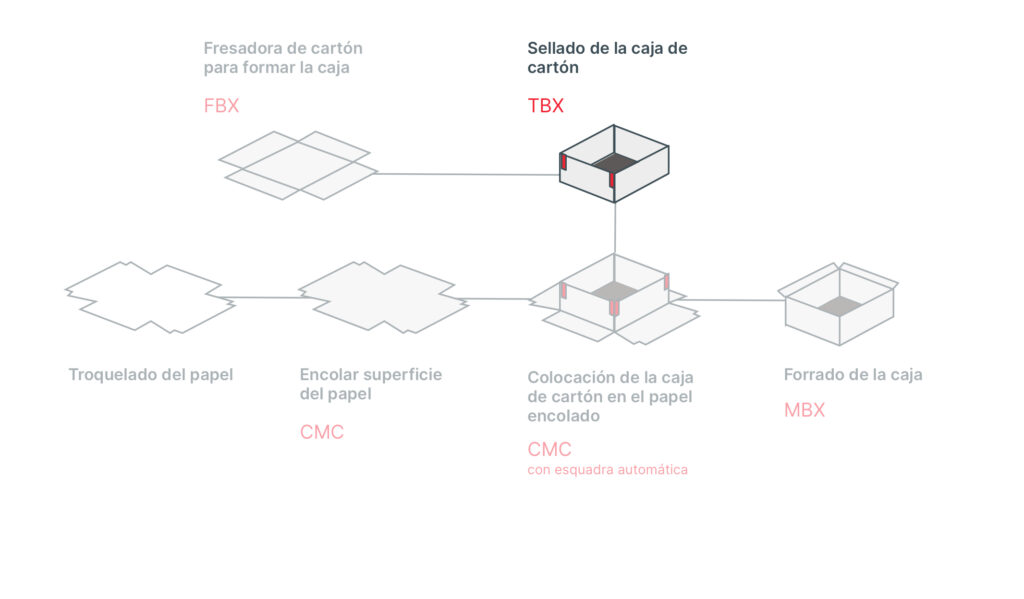

Box formers

The next step is to form the cardboard box, preparing it for lining. Our formers are capable of sealing with plastic or paper using heat.

TBX MANUAL

Simple pedal action former. Pneumatic and electric model available.

- Plastic or paper sealing

- Graduation of temperature and sealing time

- Easy adjustment and handling

- Box height from 10mm to 300mm

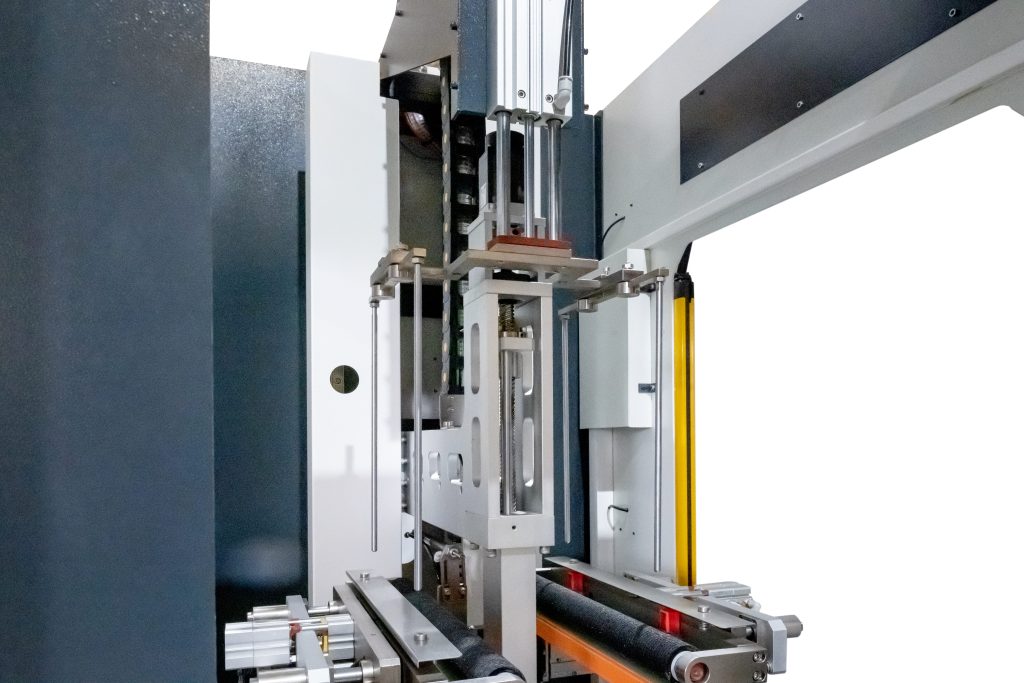

TBX-COMPACT

Automatic box former. It performs the sealing of the four corners of the box simultaneously, with the possibility of placing up to two strips of paper or plastic per corner, for greater firmness in larger boxes.

- High production (up to 50 pcs/min)

- Minimum dimensions: 80x65x15 mm

- Maximum dimensions: 600x400x120 mm

- Single or double sealing, to guarantee the sealing of larger boxes

- Possibility of working on demand with TBX-KT mat (optional)

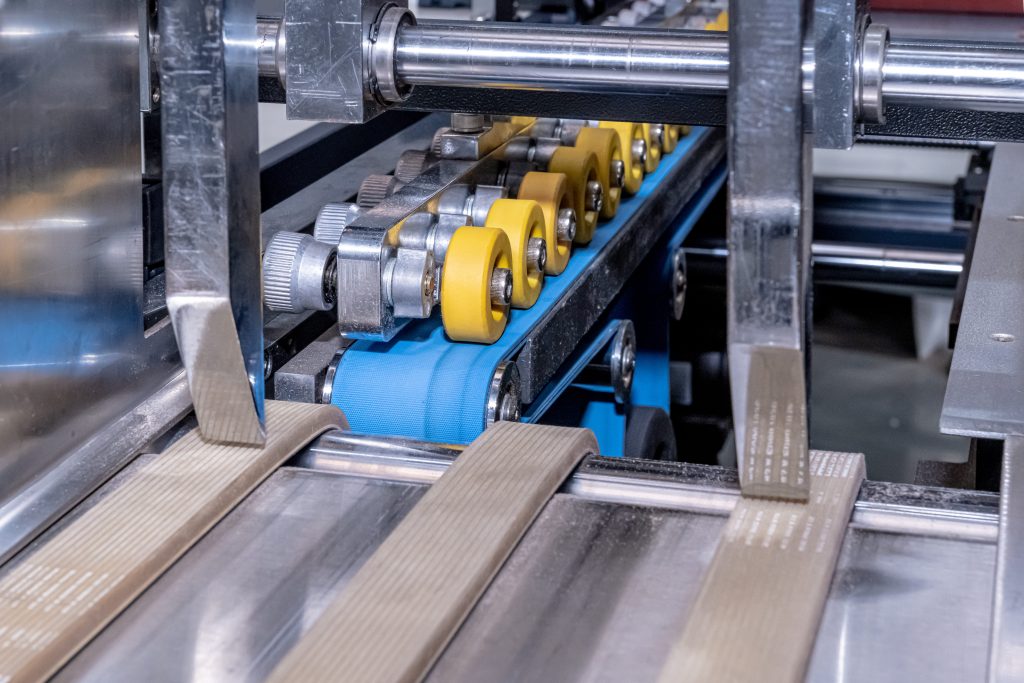

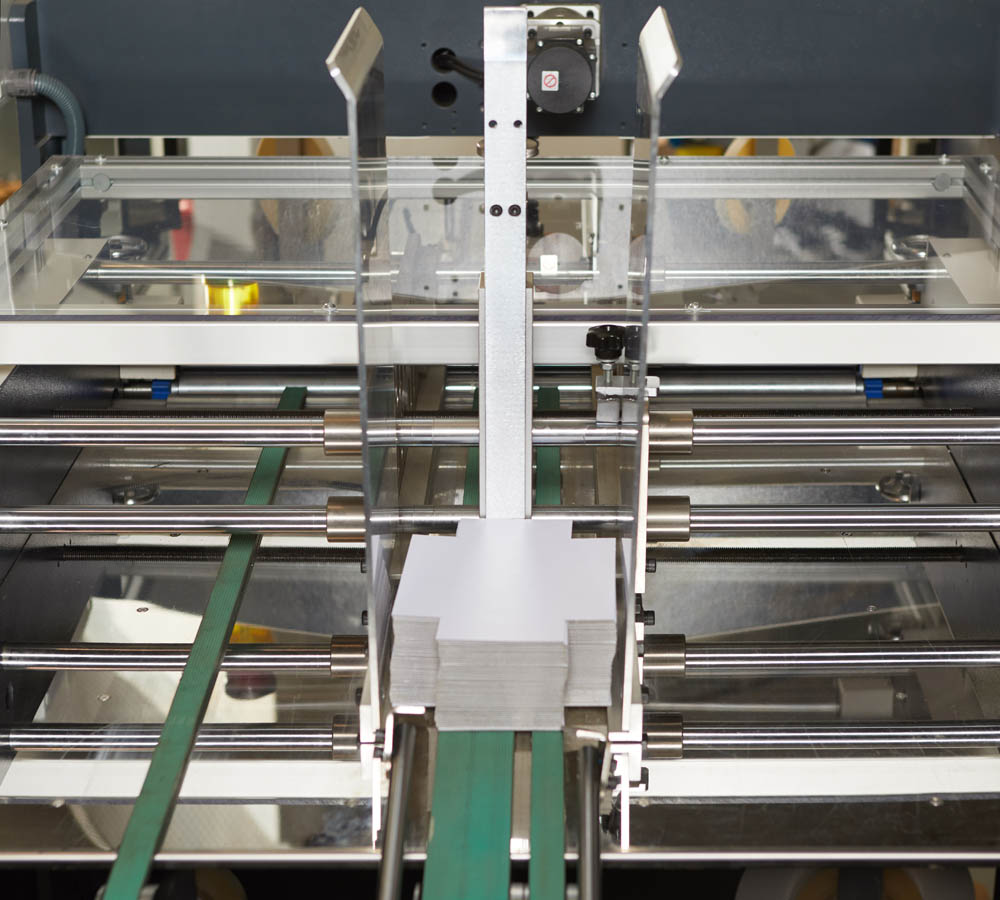

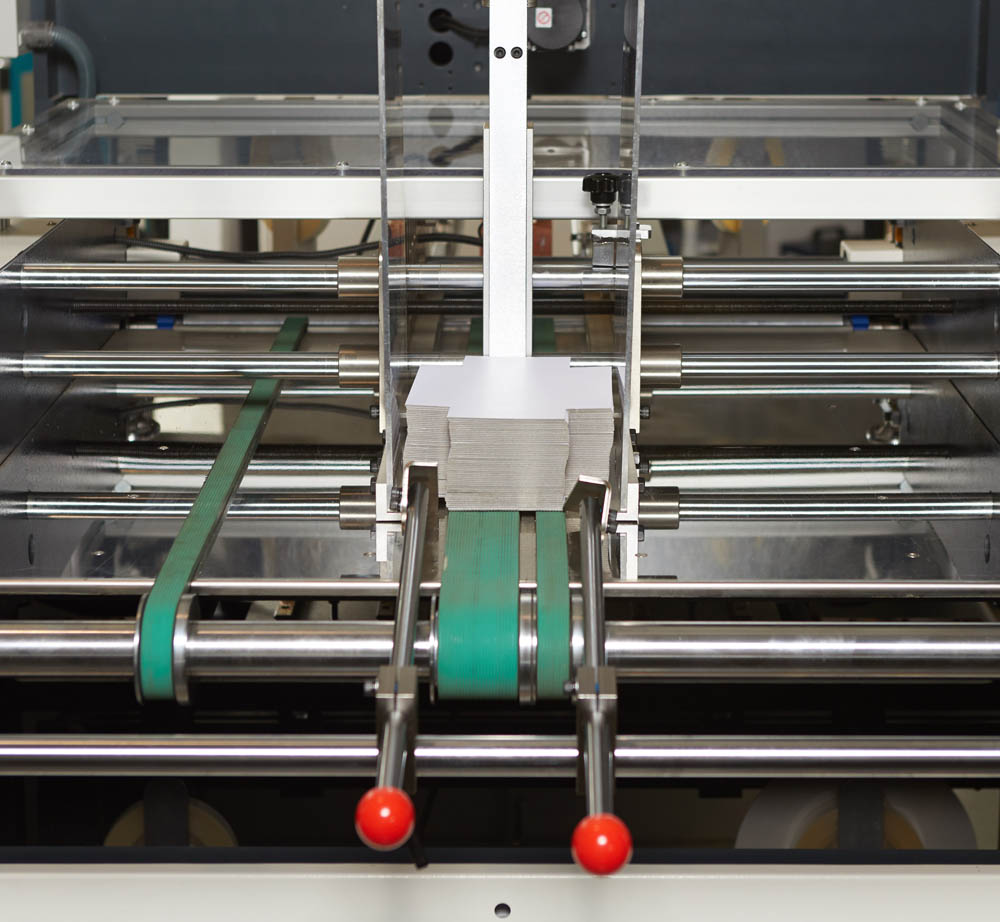

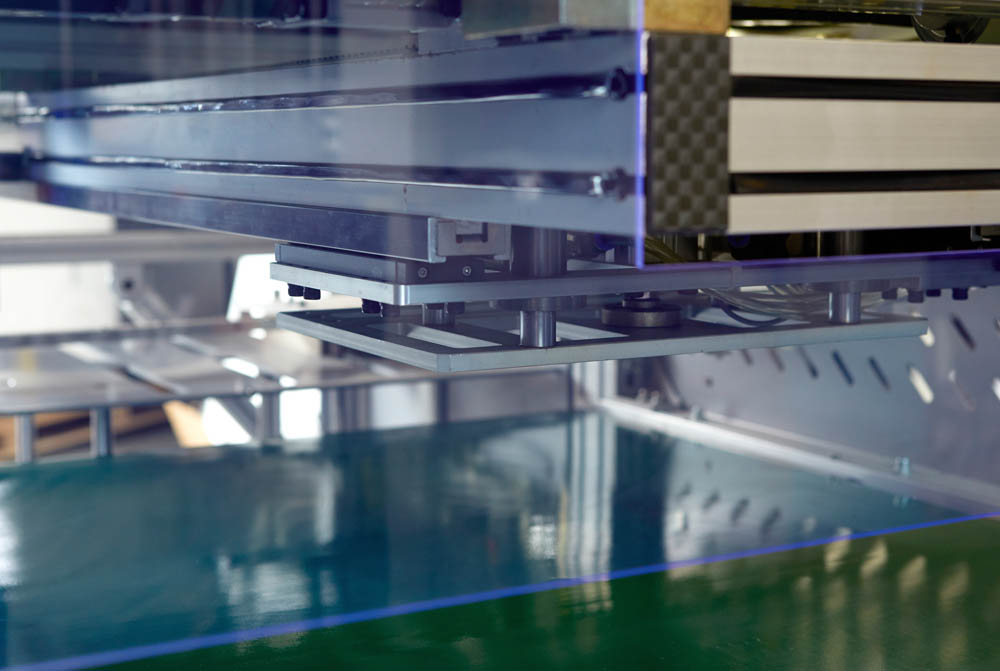

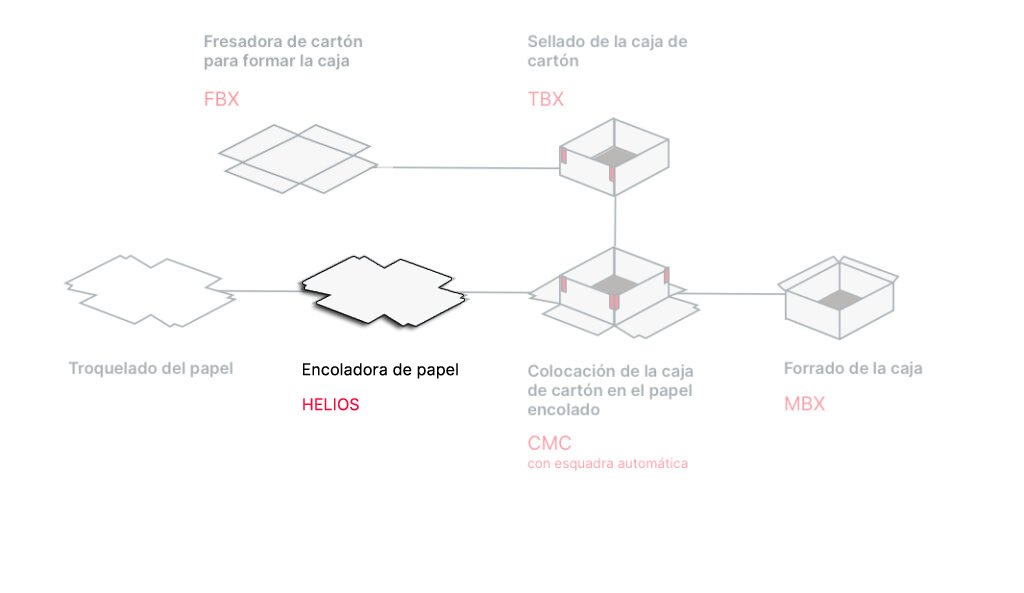

Paper Gluing

The next step in the production of the lined box is the gluing of the paper, and the subsequent centering of the formed box. They are two complex processes that require specialized machinery to guarantee the uniform distribution of the glue and positioning as quickly as possible. CMC Italia has specialized its Helios model exclusively for this process.

HELIOS

Gluer with conveyor belt for paper, plasticized paper, fabric, cardboard, cardboard and other materials for binding, folders and the manufacture of lined boxes.

- Hot and cold glue with recirculation pump

- Normal or suction conveyor belt, in different lengths

- Automatic paper feeder for packaging (optional)

- Registration stop and squares with automatic centering for packaging (optional)

- Versatile and precise, configurable for any production need

- Available in 75cm span as standard, larger sizes on request

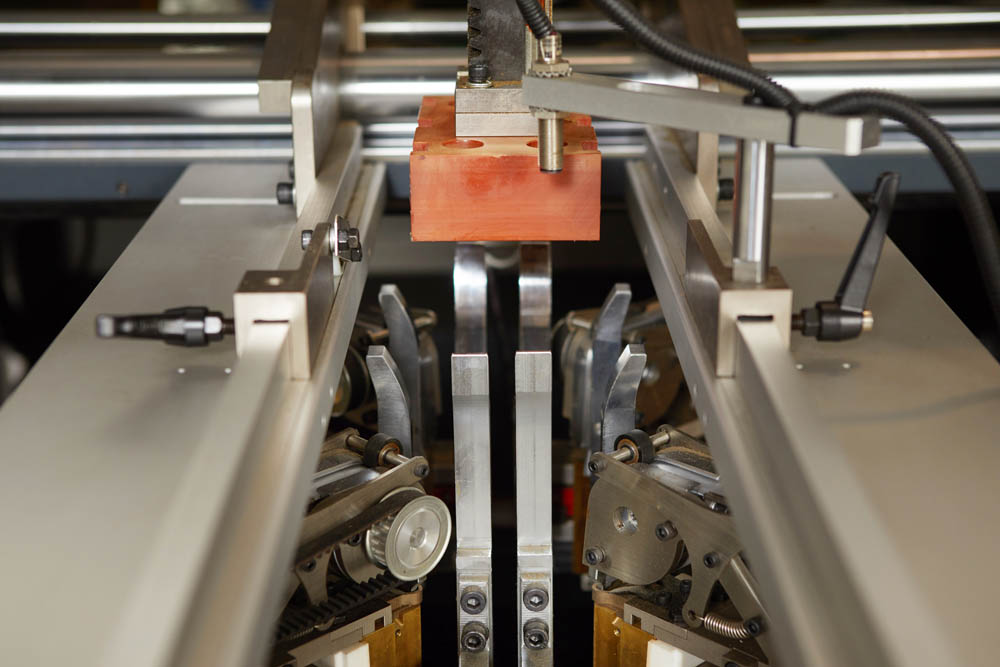

Box lining

The final step of the process is the lining of the cardboard box formed with paper previously glued with hot glue. It is recommended to use quick-drying glue, since the duration of a cycle in our machines is approximately 4.5 seconds.

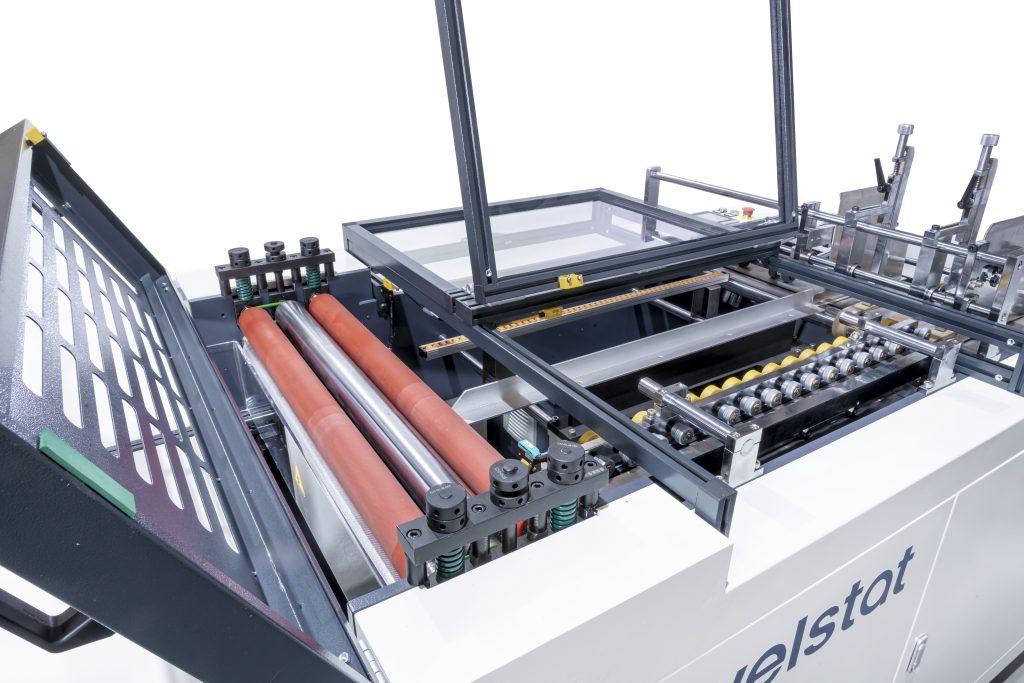

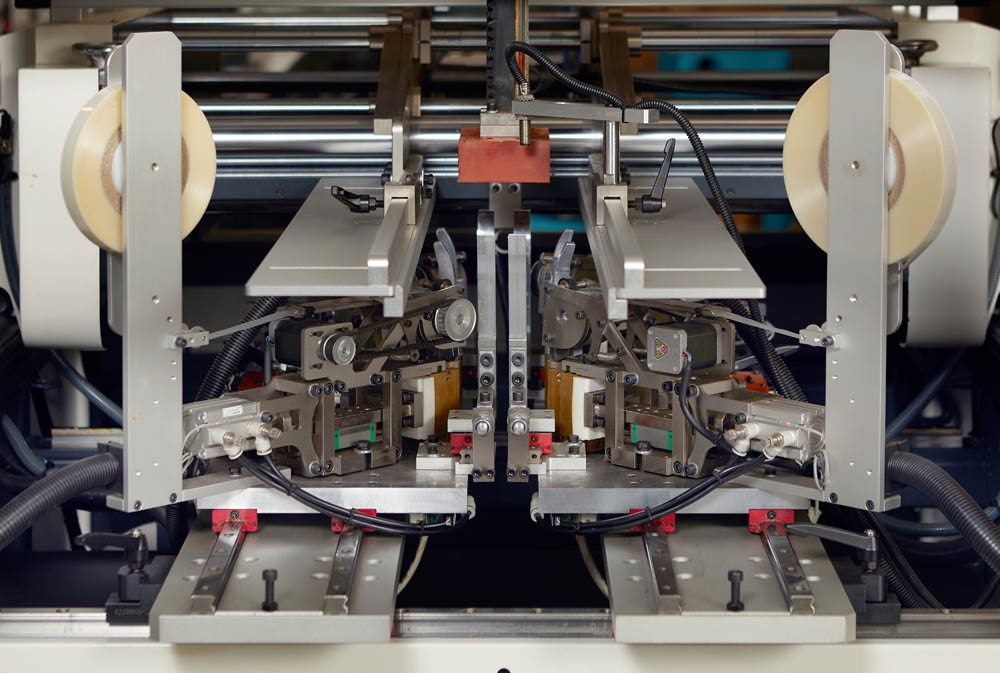

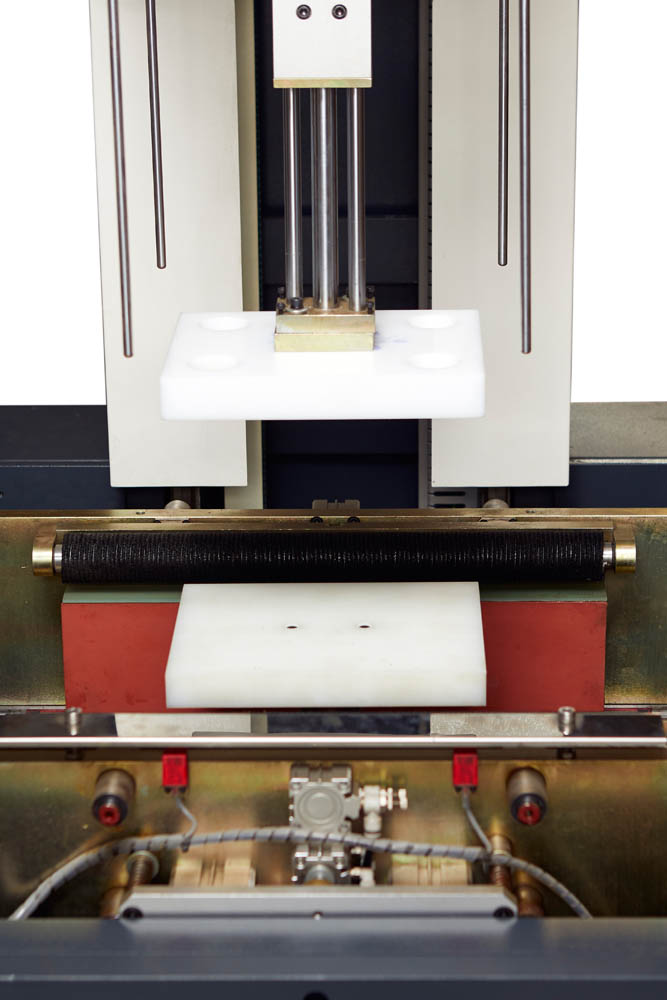

MBX-L3

Box lining machine with manual size adjustment

- Automatic, non-stop and fast

- High precision with positioning motors

- Leading brands: Schneider, Eaton, SMC, SICK

- Quick and easy size change

- PLC controlled

- Possibility of working in 3 zones

- Min. Size: 80 x 65 x 10 mm

- Max. Size: 450 x 380 x 100 mm

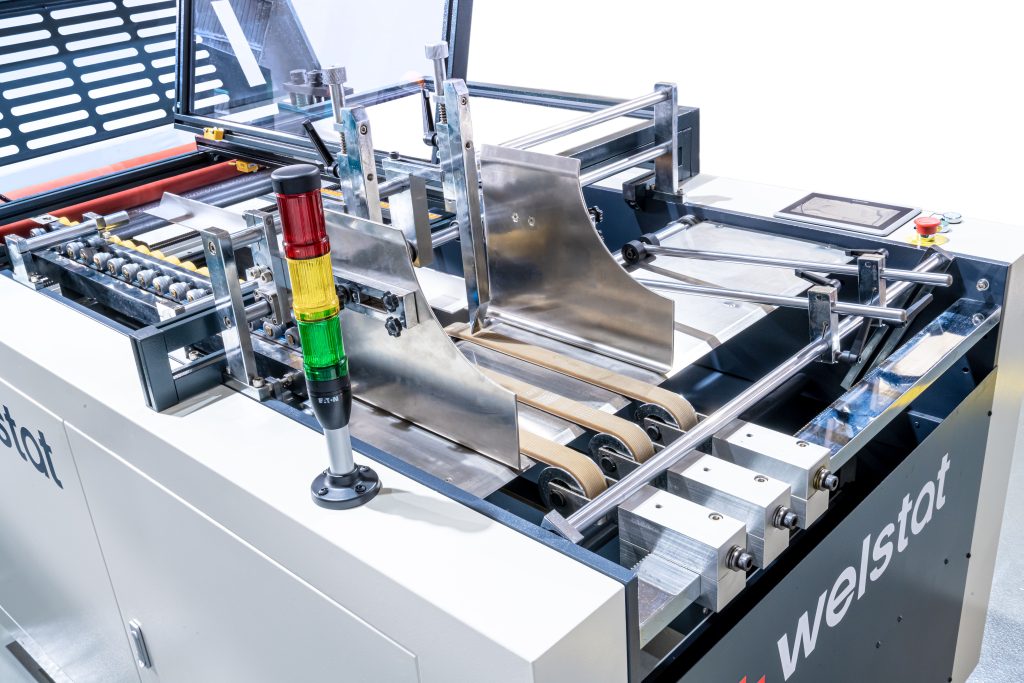

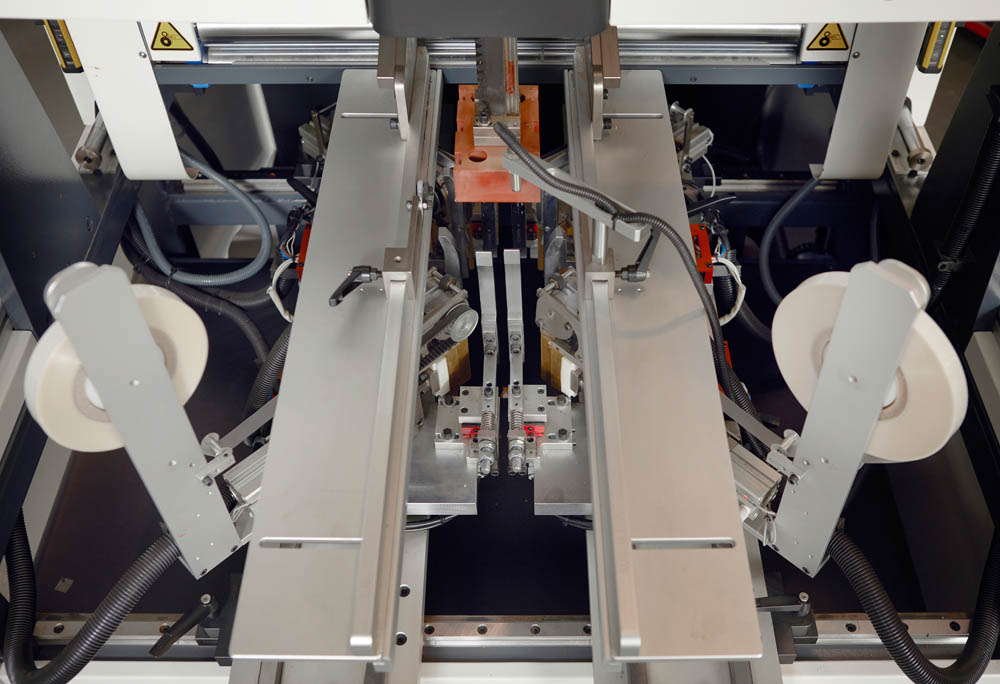

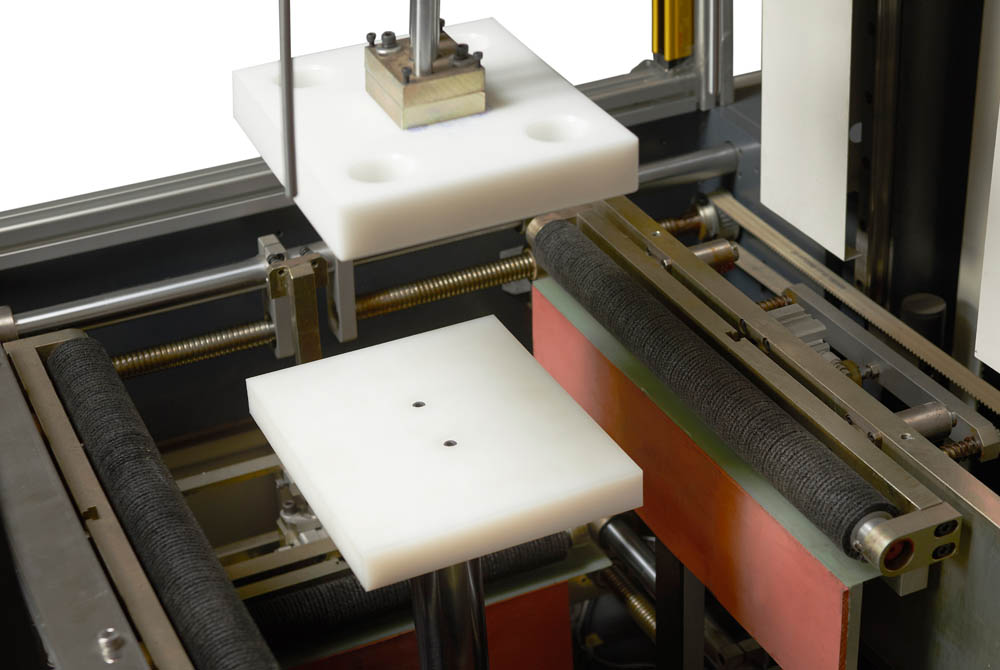

MBX-EVO

Box lining machine with automatic adjustment.

- Automatic, non-stop and fast

- Great precision with positioning motors in all its axis

- Leading brands: Schneider, Eaton, SMC, SICK

- Change of measures through touchscreen

- Memory to save the boxes made previously.

- PLC controlled

- Possibility of working in 3 zones

- Min. Size: 80 x 65 x 10 mm

- Max. Size: 450 x 380 x 100 mm

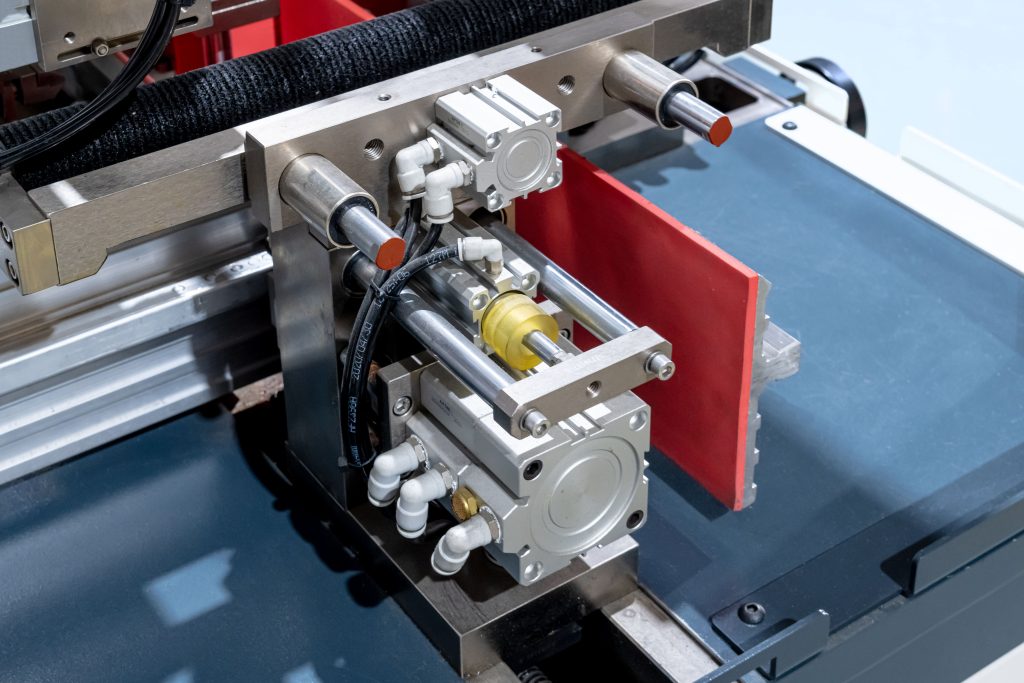

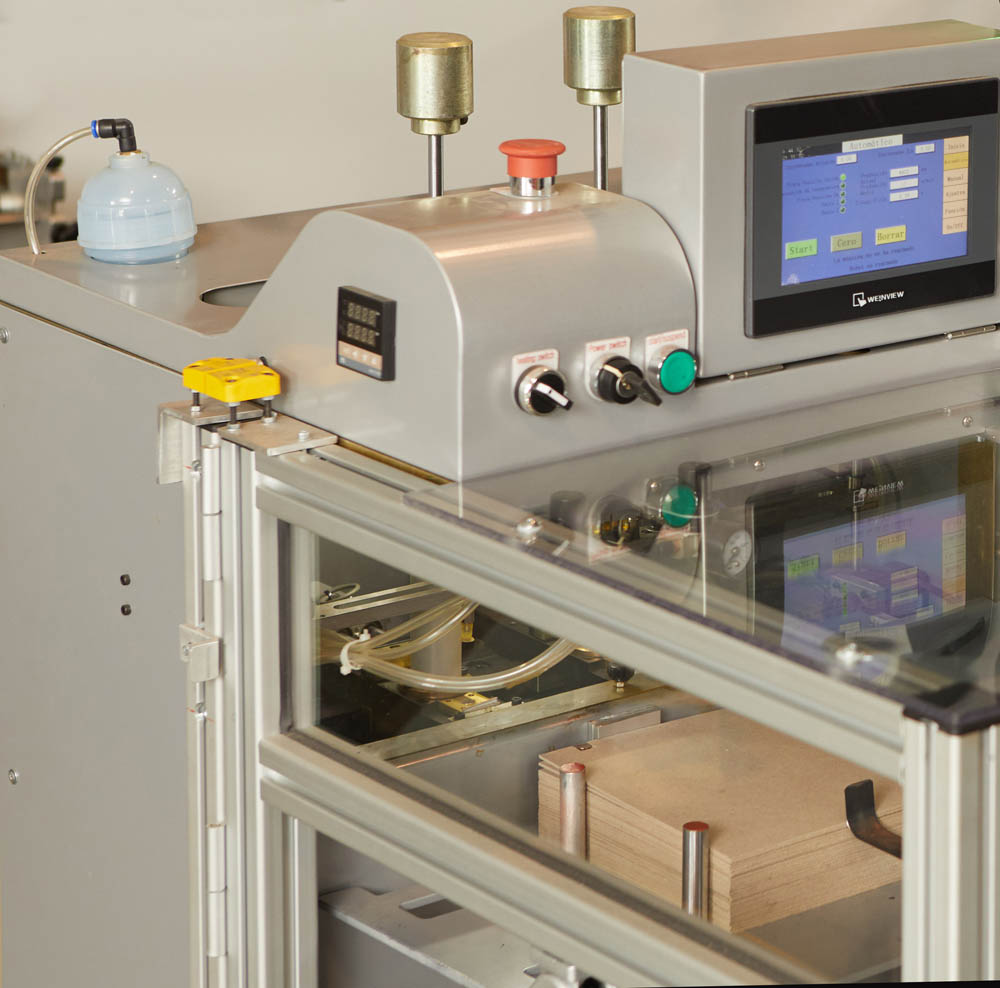

Magnet placement

In response to the growing demand for chest-type boxes, at WELSTAT we are proud to present the GAMMA, an automatic magnet placement machine for cardboard lids.

GAMMA ADVANCE

- Possibility of using hot/cold glue

- Precision by servomotors

- Up to 30 pieces/min

- Versatile and compact

- Automatic exit robot

Reliability, handling, and unbeatable technical support are the pillars on which our philosophy is based.

Download brochure

Download brochure